HM CNC Press brake 4050 mm, 225 t

# 00540095

PRESTIGE line - HPB 225 40-31

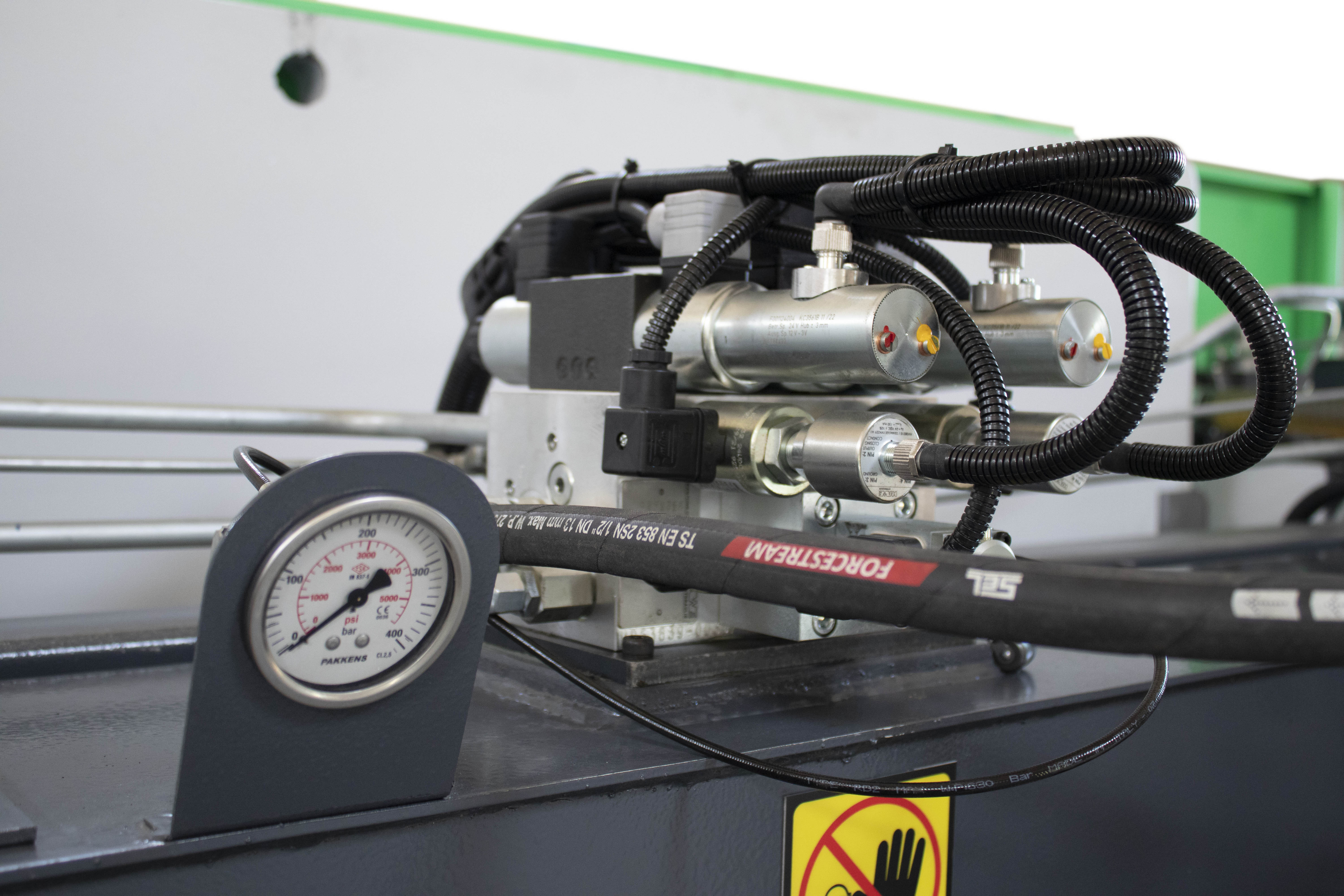

HM offers high precision and flexibile CNC pressbrakes, ideal for bending sheet metal to predetermined shapes using hydraulic force.

The machines are equipped with top quality brands for the hydraulic system and all electronic components. With its multi-axis configurations, the HM press brakes can tackle bending applications from simple to complex, efficiently and cost effectively.

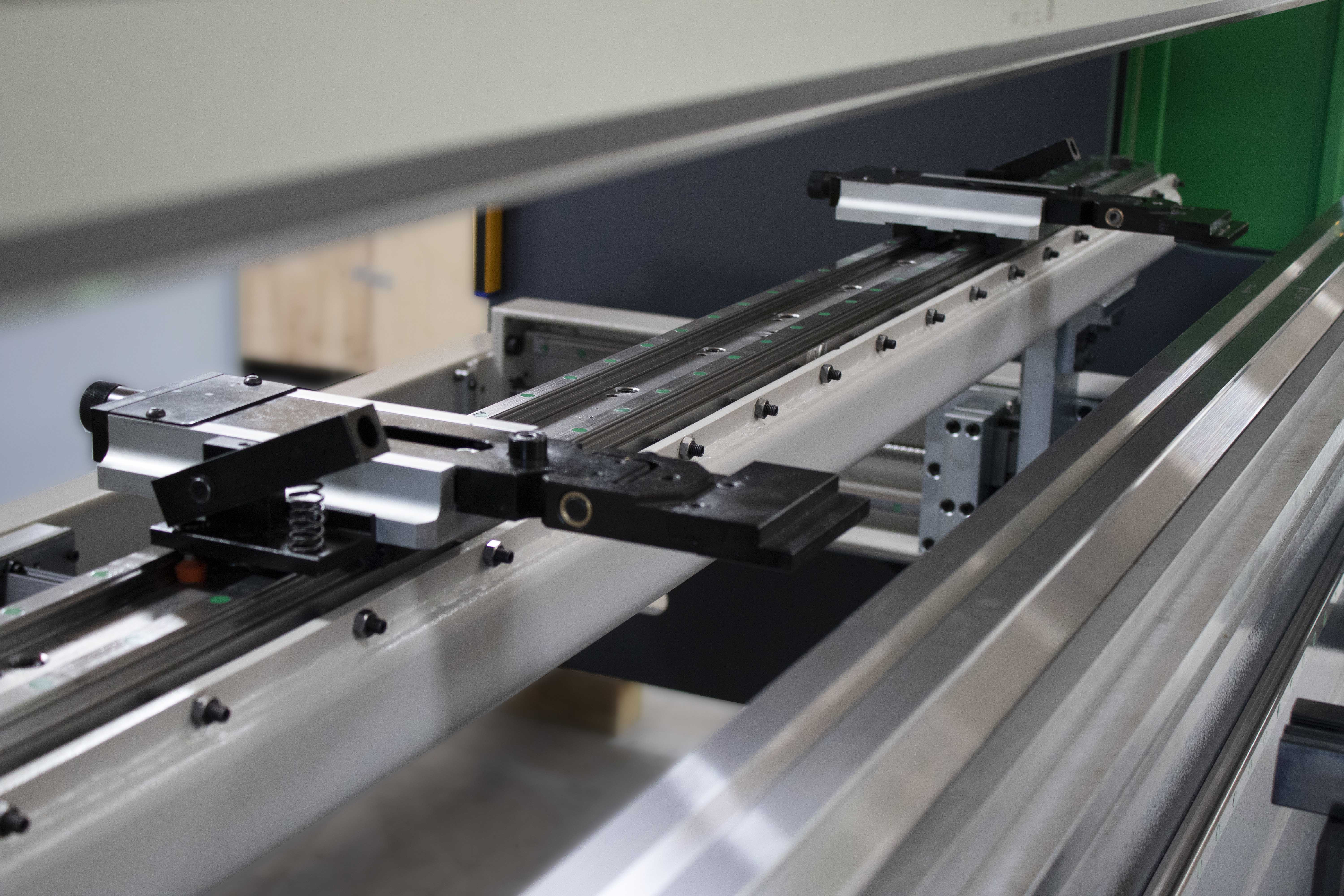

Standard features include among others Eurostamp 2067 Bottom Tool 85° (V:50, 35, 22, 16), Eurostamp 1260 Top Tool 85°, CNC Controlled Asenkron Motorized Backgauge (X:750 mm), DSP Laser Front Finger protection, manual crowning (300 tons machines), Motorised CNC crowning (400 tons over 6 m machines), Step Automation Rock graphical control, 3 axis control.

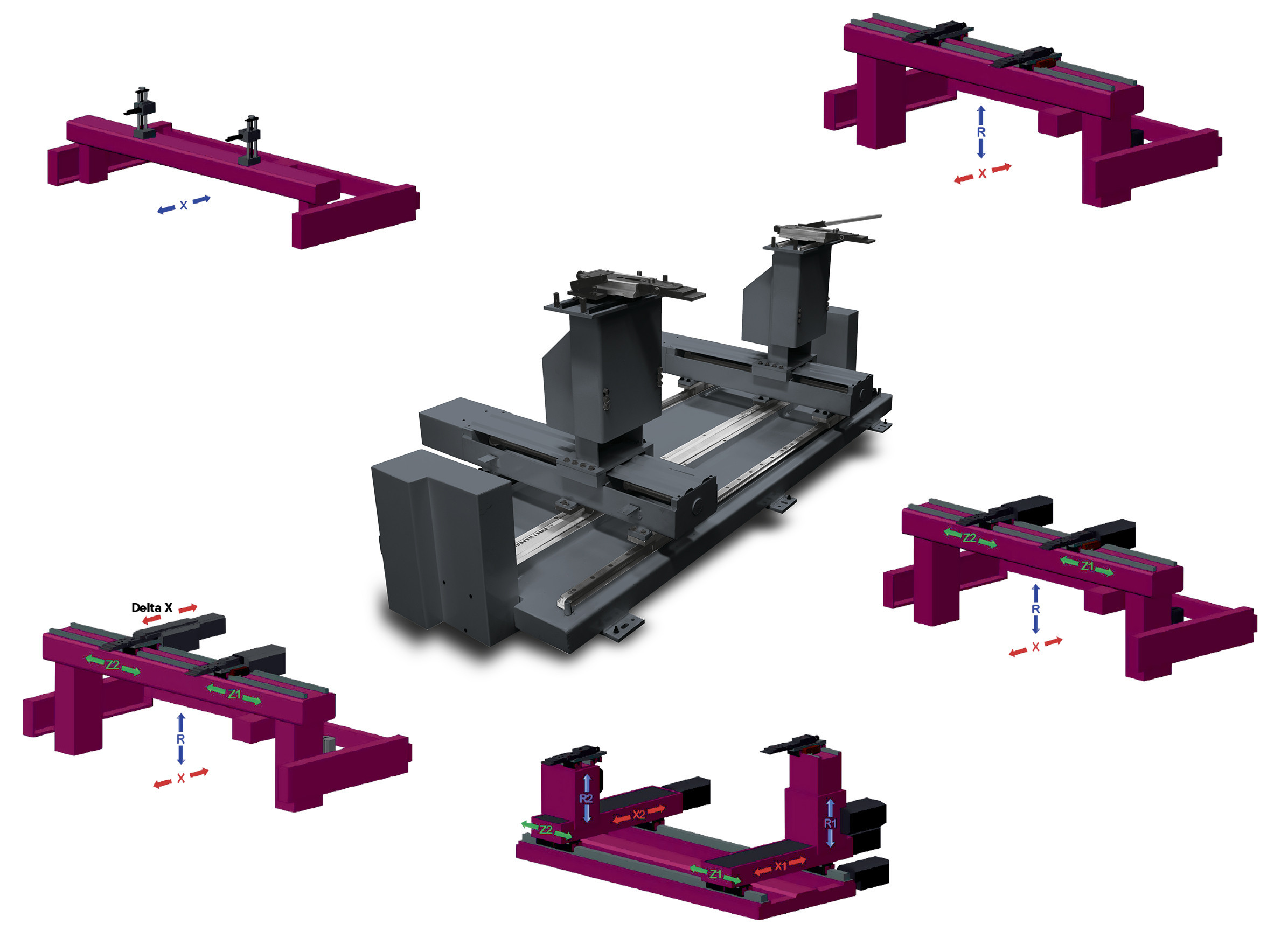

HM press brakes can be configurated to any customers need with options like:

- Manual crowning or CNC motorized crowning

- Cybelec, Delem, ESA or Step Automation control

- R axis (250mm stroke)

- X+X2 axis

- R1xR2 axis

- Z1+Z2 axis

- ATF Type6 axis back gauge

- Servo motorized back gauge

- Back gauge 1000mm

- Wila type clamping system

- and much more.